Kailong Lanfeng New Material Technology Co.Ltd

- Categories:分子公司

- Time of issue:2020-07-20 00:00:00

- Views:0

1. Company Profile

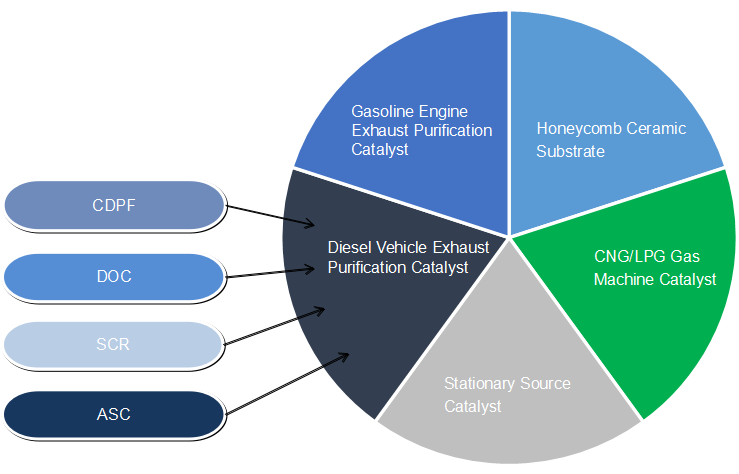

Founded in 2011, Kailong Lanfeng New Material Technology Co., Ltd. is a national high-tech enterprise integrating honeycomb ceramic substrates and vehicle exhaust purification catalyst. The company mainly produces honeycomb ceramic substrates, diesel exhaust purification catalyst (DOC, SCR, CDPF), gas machine catalyst, gasoline engine exhaust purification catalyst and stationery source catalyst.

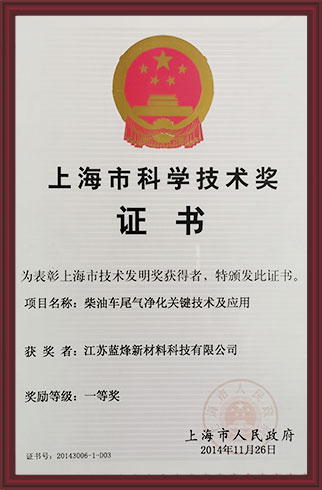

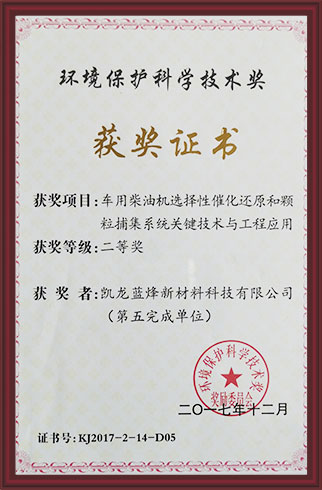

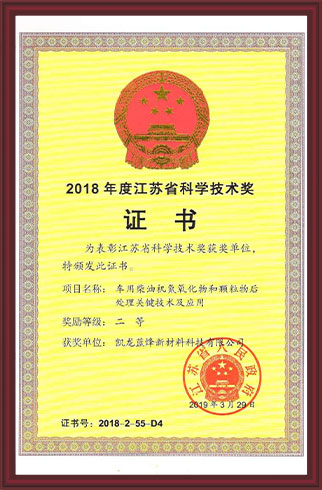

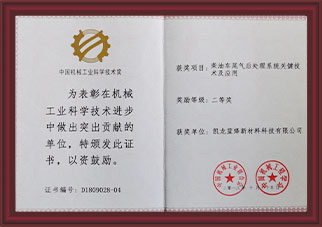

Lanfeng has undertaken 8 projects, including the national key R&D plan, the provincial Entrepreneurship and Innovation Plan, the provincial Doctor gathering Plan, the provincial technology innovation fund for science and technology enterprises, the special fund for the transformation of scientific and technological achievements, the provincial key R&D plan, the municipal key R&D plan and Zhenjiang 331 Talent Plan. The company has won the second Prize of National Science and Technology Progress award, the first prize of Shanghai Technology Invention Award, the second prize of Environmental protection Science and technology Progress Award, the second prize of internal combustion engine science and technology Progress Award, the second Prize of China Machinery Industry Science and technology Award, the second Prize of Jiangsu Province Science and technology Award and the third Prize of Zhenjiang Science and Technology Progress Award. The company has been established "Jiangsu Diesel Engine Exhaust Purification Engineering Technology Research Center" authorized by Jiangsu Provincial Science and Technology Department. The company has 175 employees, among which 20% are technical R&D personnel (4 Doctors and professors, 10 masters).

2. Main Products of Lanfeng

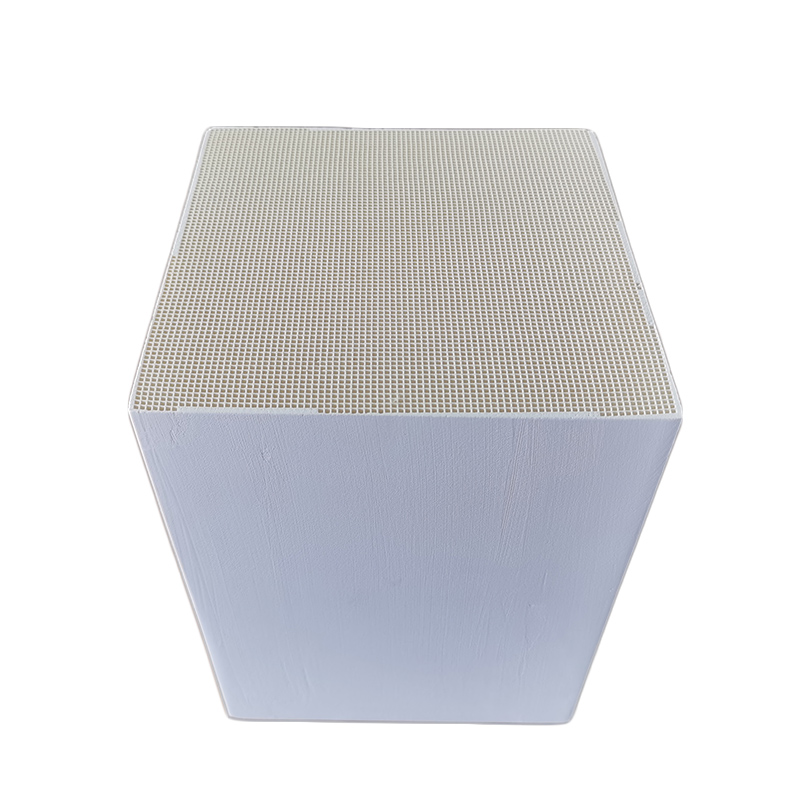

1. Honeycomb Ceramic Substrate

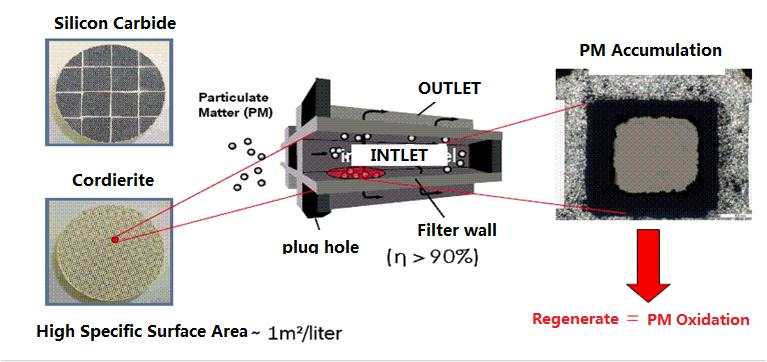

Honeycomb ceramic substrate produced by our company mainly includes straight-through honeycomb ceramic substrate and wall flow honeycomb ceramic substrate(DPF substrate for short), among which, DPF substrate can be divided into cordierite DPF substrate and silicon carbide DPF substrate according to different materials.

|

CN VI Cordierite GPF |

CN VI Cordierite DPF |

CN VI Silicon Carbide DPF |

|

CN VI 400 mesh Substrate |

CN VI 600 mesh Substrate |

CN VI 750 mesh Substrate |

|

Large Size Straight-through Substrate |

Stationery Source with Straight-through Substrate |

A Straight-through Substrate Used for Gasoline Engines |

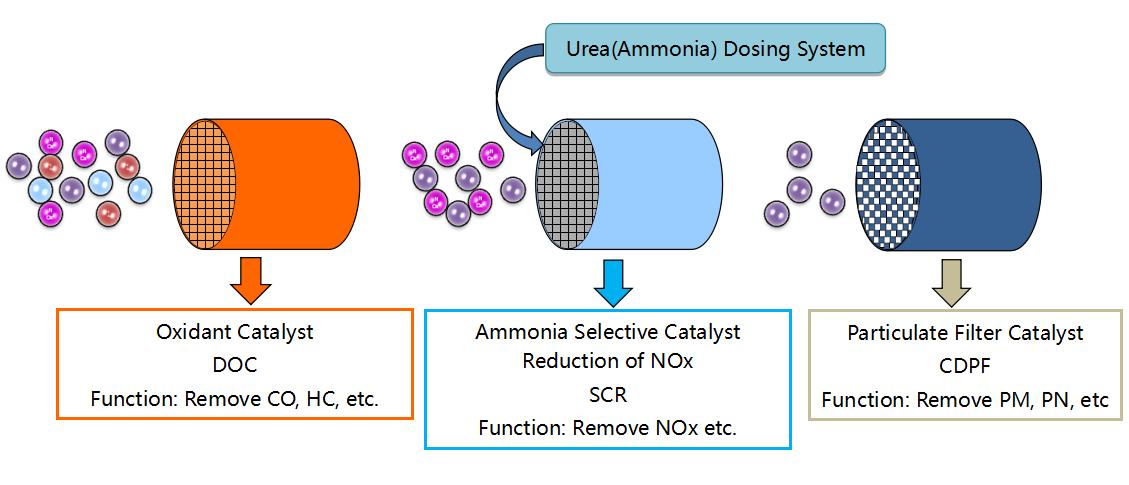

2. Diesel Exhaust Purification Catalyst

The main pollutants of diesel engine are CO, HC, NOx and PM. Catalytic purification is the mainstream technology of diesel exhaust after-treatment at present.

The principle of Catalytic Purification:

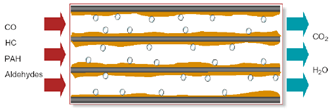

3. DOC Catalyst

DOC catalysts are mostly precious metals based catalyst such as platinum (Pt), palladium (Pd) etc.

Function and Purpose

It oxidizes HC, CO and soluble organic SOF in diesel exhaust;

Coping with SCR, DOC oxidizes NO in diesel exhaust into NO₂, creating thermal energy to improve catalysts performance under low temperature.

Coping with cDPF, DOC oxidizes NO in diesel exhaust into NO₂, which serves as the oxidation of carbon soot particles achieving cDPF passive regeneration; Soot can also directly oxidize injected fuel HC to improve inlet temperature of cDPF catalyst, and achieve active regeneration of cDPF by burning carbon particles

DOC catalyst can be used for CN V, CN VI emission standard for road application and CN IV and above emission standard for non-road application.

|

HC+O₂→CO₂+H₂O CO+O₂→CO₂ SOOT+O₂→CO₂(Partial conversion) PAH+O₂→CO₂+H₂O; NO+O₂→NO₂ |

|

|

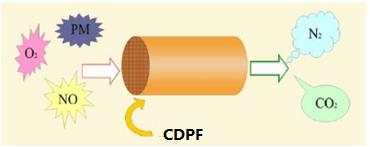

4. CDPF Catalyst

Through the filtering of the wall-flow substrate, the PM can be captured by the wall of the DPF. Under the chemical reaction of catalyst, the captured PM will be oxidizes as CO₂ and H₂O. under certain temperature conditions.

|

|

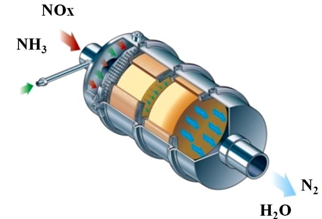

5. SCR Catalyst

Diesel SCR catalysts mainly consist of V-SCR catalysts and molecular sieve SCR catalysts. V-SCR catalyst can meet CN V of diesel engine and non-road CN III emission standards of small and medium power diesel engine; Molecular sieve SCR catalyst is divided into Cu - SCR, Fe - SCR and Cu&Fe - SCR, mainly used for road diesel engine CN Ⅵ and non-road diesel engine IV and above emission standard.

|

SCR Catalyst Reaction Mechanism 4NO+4NH₃+O₂→4N₂+6H₂0 NO+NO₂+2NH₃→2N₂+3H₂0 8NH₃+6NO₂→7N₂+12H₂O |

|

|

III Products of Lanfeng and Technical R&D

1. Technical R&D Capability

|

No. |

Patent |

Authorization No. |

Authorization Date |

Applying Date |

Patent Type |

|

1 |

The invention relates to a preparation method of honeycomb ceramics with high outer firmness |

ZL201310020209.X |

2014.4.23 |

2013.1.18 |

Invention |

|

2 |

The invention relates to a light transmission detecting device for honeycomb ceramic substrate and a method thereof |

ZL201310411137.1 |

2015.12.2 |

2013.9.11 |

Invention |

|

3 |

The invention relates to a preparation method of large size honeycomb ceramic carrier for diesel engine |

ZL201510018727.7 |

2017.7.25 |

2015.1.14 |

Invention |

|

4 |

The invention relates to a preparation method of diesel engine oxidation catalyst |

ZL201510019689.7 |

2017.7.25 |

2015.1.14 |

Invention |

|

5 |

The invention relates to a preparation method of ammonia oxidation catalyst |

ZL 201610105892.0 |

2019.2.12 |

2016.2.26 |

Invention |

|

6 |

The invention relates to a preparation method of molecular sieve based SCR catalyst |

ZL201410397060.1 |

2018.5.15 |

2014.8.12 |

Invention |

2. Standards

Industry Standard

|

|

|

IV Honor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scan the QR code to read on your phone

Kailong High Technology Co., Ltd.

Service Hotline:

Address:

No. 158, Ouyang Road, Miaotang Bridge, Qianqiao Supplementary Area, Huishan Economic Development Zone, Wuxi City.

All rights reserved:Kailong High Technology Co., Ltd. 苏ICP备14026746号 Powered by www.300.cn

400-100-4028

400-100-4028

QQ

QQ  Feedback

Feedback